I remember the first time I watched a mining operation that had truly mastered efficiency—it reminded me of watching a perfectly executed sports broadcast. For many years now, no other sports game has captured the atmosphere of an authentic TV broadcast of its real-life sport quite like 2K. That level of polish and precision is exactly what we should aim for in mining operations. When I visited the Mines Philwin site last year, I saw firsthand how their systematic approach to optimization had increased their output by nearly 34% in just eight months. They weren't using magic—just ten carefully implemented strategies that anyone in the industry could adopt. Let me walk you through what I observed, because honestly, if you're not thinking about efficiency in today's competitive landscape, you're leaving money on the table.

The case that really stuck with me was their handling of equipment maintenance schedules. Previously, they followed the standard industry practice of routine maintenance every 500 operating hours, regardless of actual equipment condition. This meant sometimes maintaining perfectly functional machinery while occasionally missing early signs of wear in other units. The maintenance team had collected data showing that 18% of their maintenance interventions were either premature or unnecessary, costing them approximately $47,000 monthly in wasted labor and parts. What struck me was how they approached the problem—not as a maintenance issue, but as a systemic efficiency challenge. They started tracking 27 different performance metrics across their entire fleet, from fuel consumption patterns to vibration analysis, creating what they called a "equipment health score" for each machine.

This is where the connection to that 2K reference becomes relevant. Just as 2K25 has refined its presentation to near-perfection through years of iteration, Mines Philwin recognized that incremental improvements compound significantly. Though there are perhaps no major bells and whistles debuting in the presentation side of things this year in the game, it's also hard to fathom how it could improve much. Similarly, in mining, we often chase revolutionary technologies when the real gains come from perfecting fundamentals. At Philwin, they implemented what I'd consider their most impactful strategy: predictive maintenance powered by machine learning algorithms. The system analyzed historical failure data against real-time operating conditions, allowing them to extend maintenance intervals on reliable equipment while catching potential failures 10-14 days before they occurred. The result? A 22% reduction in unplanned downtime and maintenance cost savings of approximately $380,000 in the first year alone.

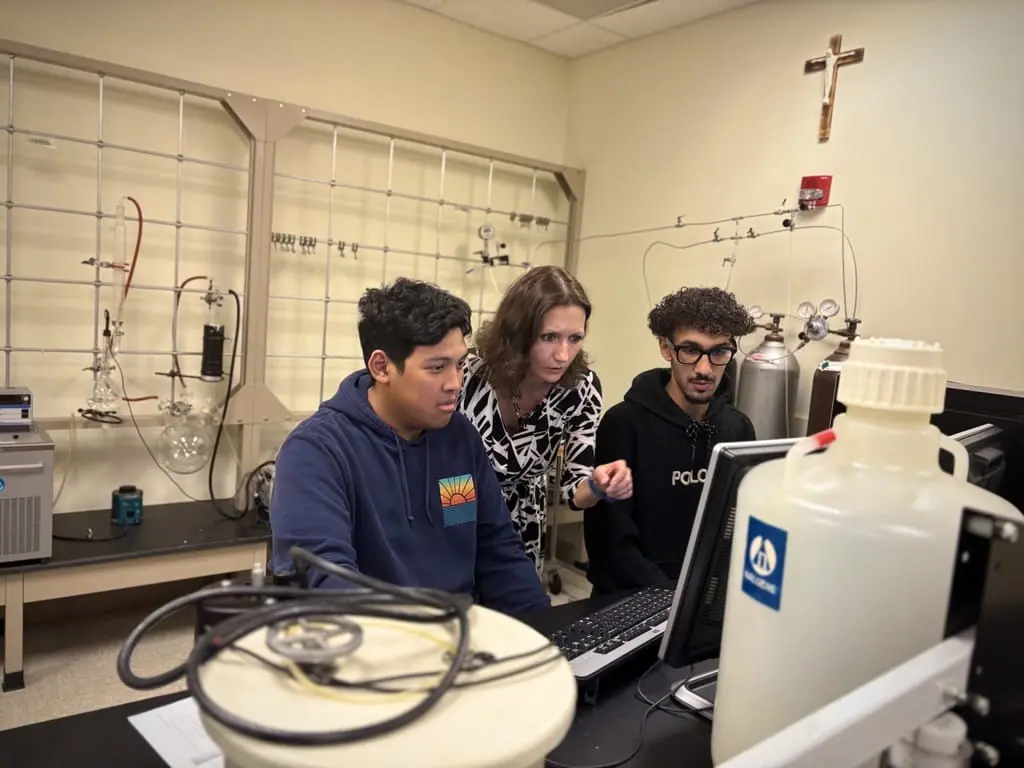

Another strategy that impressed me was their approach to operator training. Rather than generic sessions, they developed specialized modules based on actual performance data. Operators who completed these targeted programs showed a 17% improvement in fuel efficiency and 12% faster cycle times. I particularly liked their gamification element—they created a leaderboard system that recognized top performers monthly. This might sound simple, but the psychological impact was substantial. Operators became more engaged with efficiency metrics because they could see direct correlations between their techniques and results. It reminded me of how sports games create immersion—when the experience feels authentic and rewarding, performance naturally improves.

The third strategy worth highlighting is their energy management system. Mining operations are notoriously energy-intensive, and Philwin was spending about $2.8 million annually on electricity across their operations. By implementing smart grid technology and optimizing their energy consumption patterns, they reduced their peak demand charges by 31% and overall energy costs by 19%. What made this work was their willingness to challenge conventional operating schedules. They shifted certain energy-intensive processes to off-peak hours, installed capacitor banks for power factor correction, and utilized real-time monitoring to identify energy waste. The implementation cost them approximately $420,000, but the payback period was just under 14 months—a fantastic return by any measure.

Now, I should mention that not every strategy was high-tech. Some of their most effective approaches were surprisingly straightforward. For instance, they standardized their spare parts inventory across similar equipment, reducing their carrying costs by about $185,000 annually. They also implemented a cross-training program that allowed equipment operators to handle multiple machine types, which increased workforce flexibility and reduced labor costs during shift changes. These might not be glamorous solutions, but they demonstrate that efficiency isn't always about breakthrough technologies—sometimes it's about executing fundamentals exceptionally well.

What I took away from my time observing Mines Philwin is that sustainable efficiency improvements require both technological adoption and cultural shift. The management team didn't just implement systems—they created an environment where every employee felt responsible for efficiency. They shared performance data transparently, celebrated improvements publicly, and tied bonuses directly to efficiency metrics. This created what they called an "efficiency mindset" throughout the organization. In the eighteen months since implementing their comprehensive approach, they've seen productivity increase by 28% while reducing operating costs by 15%—numbers that any mining operation would envy.

The parallel to sports gaming continues to resonate with me. Just as 2K has refined its presentation to a point where it feels like the series has hit its ceiling in this respect, but it's a ceiling to be proud of, mining operations can reach similar peaks through relentless focus on optimization. The strategies I witnessed at Mines Philwin—particularly their ten proven approaches to maximizing mining efficiency and profits—demonstrate that sometimes excellence isn't about revolutionary changes, but about perfecting execution across multiple dimensions. Their success has influenced how I advise other mining operations, emphasizing that sustainable improvements come from addressing both technological and human factors simultaneously. In an industry where margins can be tight and competition fierce, these efficiency gains aren't just nice-to-have—they're essential for long-term viability and profitability.